Standard

- Three injection phases

- Color touch screen panel

- Fully P/Q-controlled machine operation

- Adjustable parameters for the injection phases

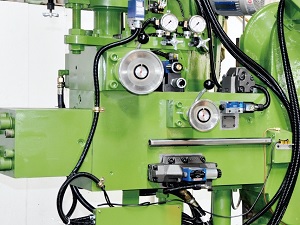

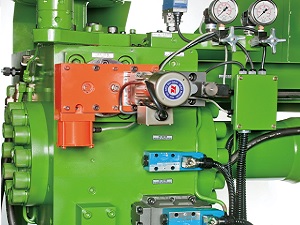

- Energy-saving P/F valves

Main pressure control system adopts variable and proportional valves to increase efficiency and to extend service life.

This design shortens the time for intensifying pressure and increases density for workpieces. Since this type of accumulator is not affected by oil impurity, it reduces maintenance costs.

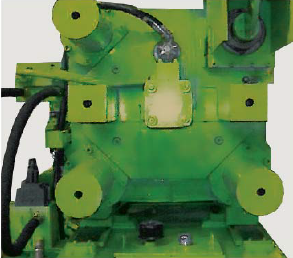

Toggles are equipped with self-lubricating bushings, and all toggle points are lubricated with slideway oil No.68. It provides better tolerance for toggles under high pressure.

The machine stops immediately when the operator opens the safety door. Besides, this can reduce the failure rate by protecting the machine from environmental pollution.

The design enables an operator to unload the upper tie bar from the front platen. It provides greater convenience especially for dies with hydraulic cores.

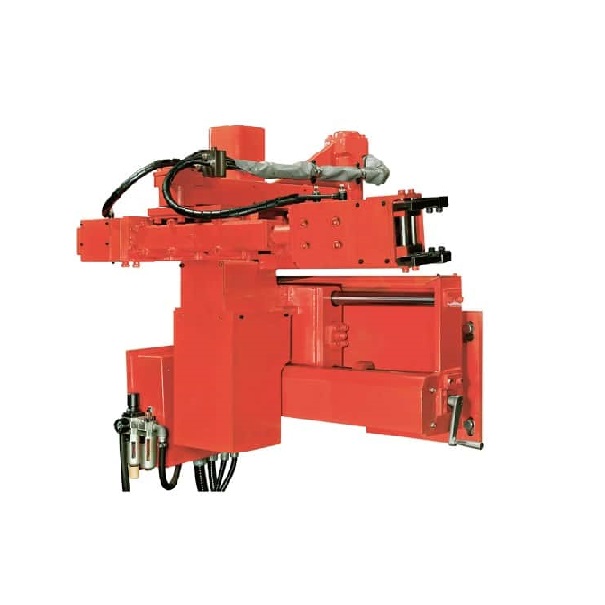

Both injection position and cylinder can be adjusted according to the design of casting or the gate position of mold.

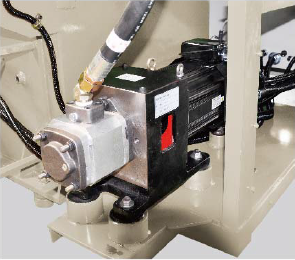

The servo-hydraulic system is more efficient and saves energy up to 35% by precisely controlling power.

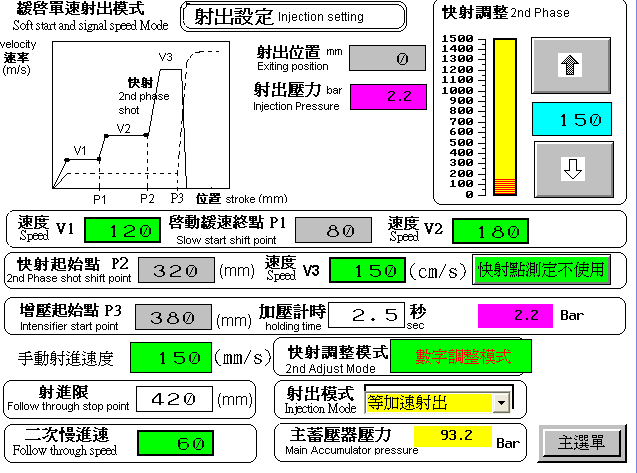

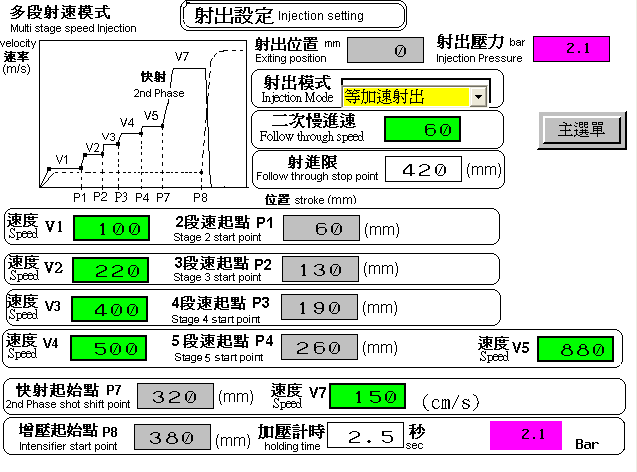

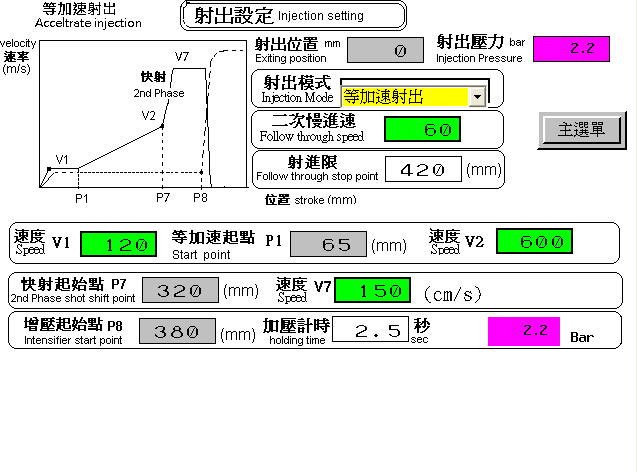

It provides a digital control for multi-phase injection speeds and exhausts air from the barrel and die cavity.

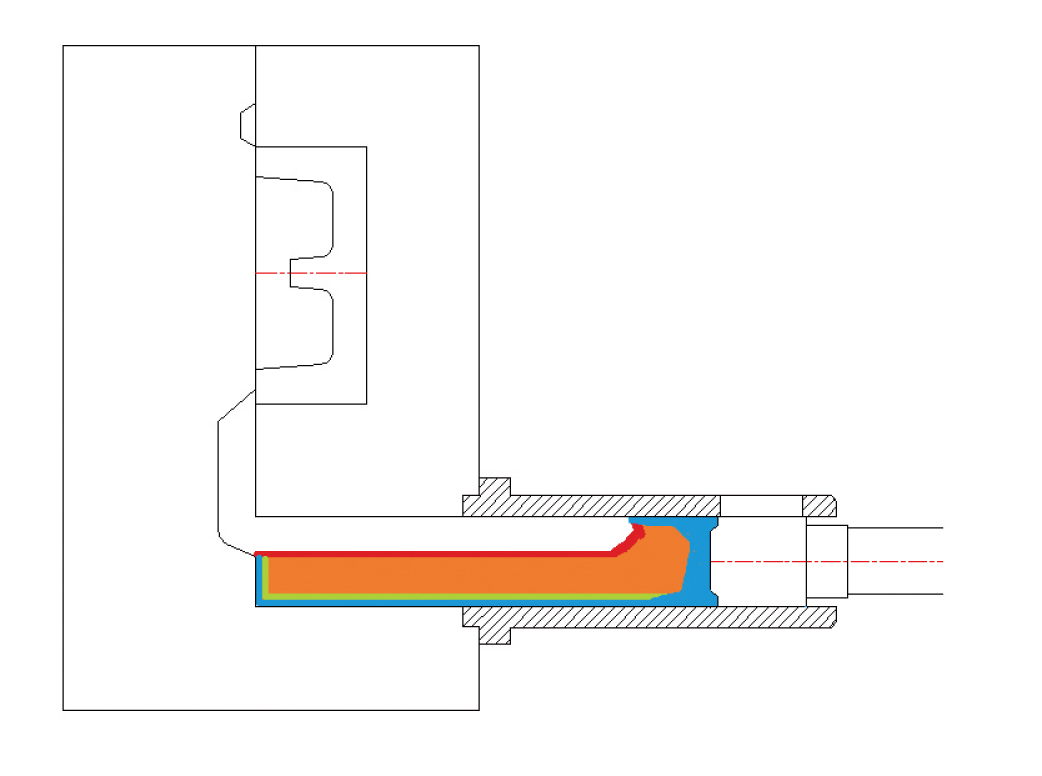

Full Test analysis simulates the die casting process with multi-phase injection control. The function helps an operator to observe flow of aluminum liquid during forming and to make a corresponding solution, and thus making sure to achieve a fully-filled barrel before second-phase injection.

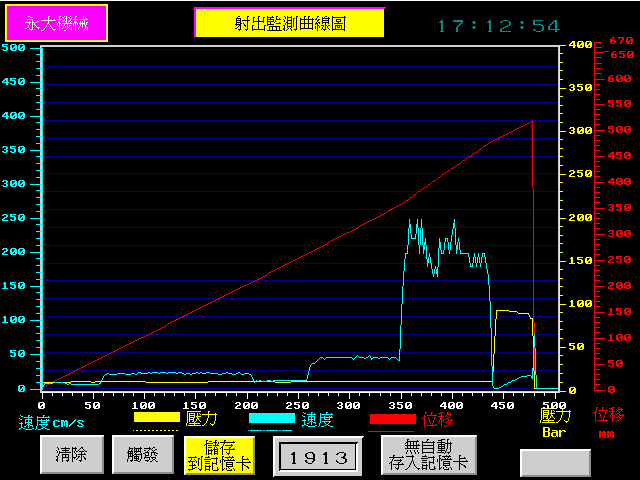

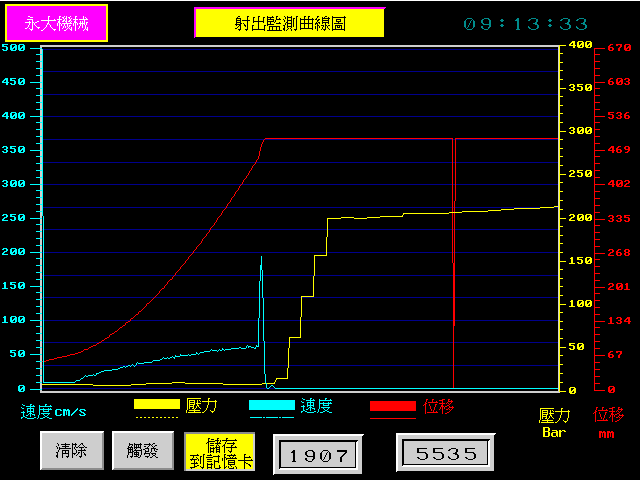

In the cold chamber die casting process, molten metal contacts with air, causing air swelling. It causes cavities and influences the quality of the product. A proper selection of critical low injection speed can ensure molten metal flows in the barrel smoothly without generating any swelling gas.

Temperature gap between molten metal and barrel wall causes a cold and solid layer on the barrel wall. The function can help operators to observe swelling gas or wrapped gas during feeding and thus to adjust the temperature and the injection speed.

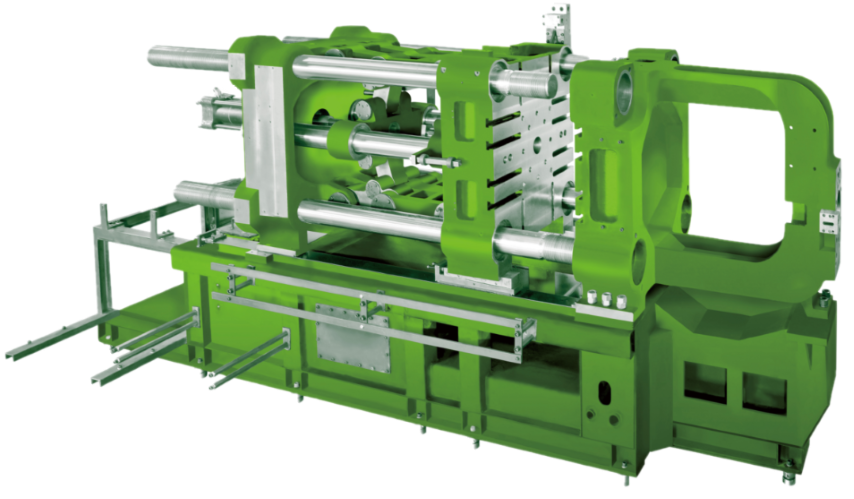

The series has been developed into a complete series of cold chamber die casting machines from 150 tons to 800 tons.

The advanced series include all features of the V3C series. Besides, it features an integrated injection circuit and two sets of independent accumulators. It provides customers with a more efficient production line and shorter cycle time. Thus it can improve productivity and reduce production cost.

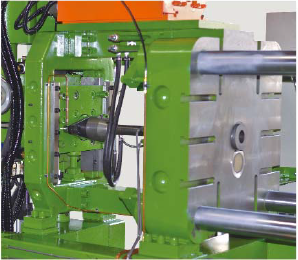

The specially-designed manifold minimizes hysteresis of hydraulic response and boosts injection response. Additionally, the integrated injection circuit is easy to maintain and therefore saves more time for maintenance.

Injection circuit unit utilizes two sets of independent accumulators. It provides pressures for first-phase injection, second-phase injection, and intensified injection function. More stable intensified pressure can be offered by an independent intensifying accumulator.

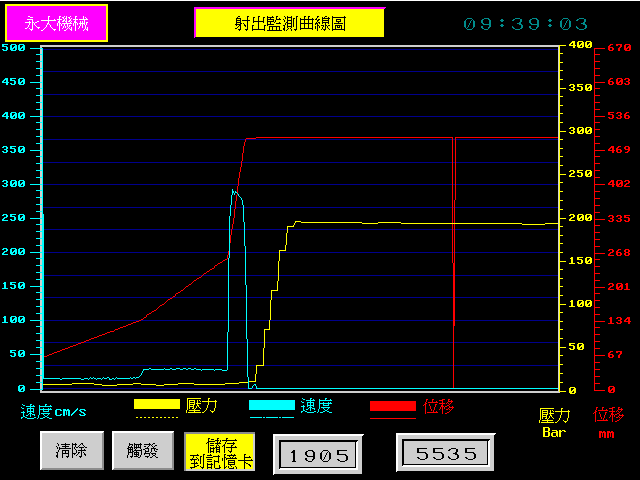

Injection unit allows adjustments of various parameters, such as pressure buildup for first-phase, second-phase, intensified pressure value, and injection pressure value. etc. Sensors in each part of our machine return values of injection speed and pressure to controller. Then the controller compares the difference between the actual injection value and the setting value to do fine-tuning. In addition, operator can understand injection situations through curve shown on the display.

Gravity Die Casting is commonly known as die casting machine. It is generally used to process hpdc machine that are light in weight. This is one of the oldest forms of aluminium casting machine.

The main difference between both the auto extractor due to the various structures. Hot chamber and cold chamber auto ladler have an entirely different structure of casting chamber. In the auto sprayer, a piston is used to force the metal into a die cavity.